How to Select the Best Welding Electrode

Welding is a process in which metals or thermoplastics are heated and melted so they can be fused together. Here electric power is used to create an electric arc, which in turn generates heat to melt the metals. Skilled technicians work with the welding electrode to conduct current through a workpiece and fuse two pieces together. This is what happens during arc welding. The electrode can either be consumable or non-consumable. Consumable electrodes can be gas metal arc welding while non-consumable electrodes can be gas tungsten arc welding.

The selection of these electrodes depends on factors such as metals that need to be welded, welding procedure and the environment in which you use this electrode for welding.

Welding accessories suppliers in UAE can help you choose the right electrodes for your purpose. This plays an important role in the quality of the welded metal. If you want the fused material to last longer it’s better to research a bit on the types of electrodes and their respective applications.

In the remaining part of this blog let us try to have a look at the factors determining selection of welding electrodes:

This section will enable you to select appropriate welding electrodes suiting your requirement.

Metals to be welded: Before buying, check the material compatibility of the welding electrode. Certain electrodes will only cater to the welding of certain metals. For example, if you want to weld steel or cast iron Shielded Metal Arc Welding Electrodes should be selected. Similarly, there are particular electrodes for aluminium or other non-ferrous metals.

Welding Procedure: Each electrode is designed to give best results for certain procedures only. If you take the SMAW electrodes mentioned in the previous case it has its method of welding. Using incompatible welding procedures will give poor quality welds.

This rule is also applicable to other electrodes such as Gas Metal Arc Welding electrodes, Gas Tungsten Arc Welding electrodes and the Flux-Cored Arc Welding Electrodes.Quality of weld: If you’re looking for weld with high deposition rates along with versatility in weld positions, you can go for the FCAW electrodes mentioned earlier. Each welding electrode has their level of efficacy.

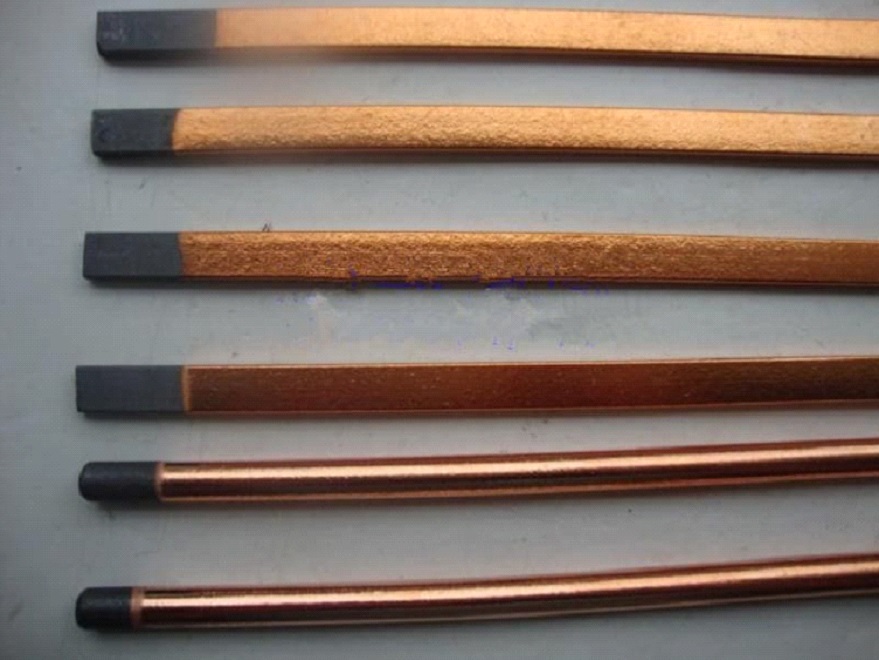

Machine compatibility: Welding accessories suppliers in UAE can provide you with welding electrodes of different size and diameters. It’s recommended to check the measurements of your welding machine before buying an electrode. The machine and electrode should be compatible.

It is also advised by experts to factor in the thickness of the weld required, before going for a welding electrode of a particular size.Environment: Some electrodes work best indoors. Some electrodes are okay to work outdoors. So it is necessary to consider your work environment before going for a particular electrode for welding.

Thus, the efficacy of an electrode in welding depends on several factors. There are different types of electrodes and they come in different sizes too. It is important to consider each aspect before going for a particular type or size of electrodes. The factors which have to be considered for selecting the best welding electrode for your purpose ranges from welding procedure to nature of environment.

Looking for a dedicated company with state of the art welding equipment to get the best welding electrodes?

With years of experience Bright Weld Middle East FZE is the best welding accessories suppliers in UAE.