A closer look at pipe cutting machines and their applications

Cutting pipes and tubes is common in metal fabrication. We'll discuss the many pipe-cutting processes utilised in the industry for plumbing parts, pipelines, handrails, compressed air systems, and other structures. Cutting pipes and tubes is frequent with Pipe Cutting Machine in UAE.

Pipe cutters provide clean, precise cuts faster, easier, and more convenient than other methods. Pipe cutters made crisp, clear cuts with little deburring. This makes pipe cutters popular among technicians.

Tools for cutting pipes work how?

Pipe cutters cut pipes using razor-sharp wheels. These wheels can penetrate the material and increase rotations. The number of rotations needed to cut a pipe depends on its material, size, and thickness.

Pipe cutting also requires blade sharpness. Pipe cutter models work differently.

Pipe Cutting Machine Types

Many pipe-cutting machines have improved because of technology. Technicians choose pipe-cutting machines based on pipe type and thickness. Let's examine pipe cutter types and materials they can cut. Pipes are classified by material: plastic, steel, copper, and aluminum. The most popular pipe-cutting procedures are cold and hot. Examine them carefully.

The Cold Cut

Cold cutting involves pipe cutting without heat or sparks. Due to its safety, this pipe-cutting process is commonly employed in hazardous areas. This technique avoids serious accidents by using little heat.

Hydrocarbon cutting involves heat and spark, thus it must be done carefully. Cold cutting in various industries will make operations safer. Cold cutting is used in cutting-intensive sectors due to safety and cost. Compared to hot pipe cutting, cold cutting is cheaper.

It speeds pipe cutting and eliminates hand grinding. Also, explosions are unlikely. This pipe-cutting method is air-free and does not require preapprovals because it generates no heat or sparks.

Cold Pipe Cutters

The cold-cutting machines fall into this group. Their portability, durability, lightweight, and compactness make cold cutters remarkable.

These devices were debuted in 1949 in various variants. Material, precision, and cost determine which machines are used.

Cold Cutting Machine Classification

Pneumatic and hydraulic cold-cutting machines are categorised by the drive mechanism. Many Pipe Cutting Machine in UAE are available, including split frame cutters and clamshell lathes.

Circle-shaped machines can wrap around pipes to be sliced in half and hinged. Pipe cold-cutting machines are classed by size and capability as low profile, mid-size, or heavy duty. Few other tools cut cold pipes. They are:

- Bandsaws

Bandsaws are typically used in chemical industries for non-precision cutting. Pipe cutting using bandsaws requires coolants because the cutting surface gets hot.

- Diamond Wire Cut

Diamond When precision is not needed, wire cutting and bandsaws are utilised. Hydraulic energy powers them. When cutting piles, pipelines, and caissons, diamond wire cutting is best.

As the name implies, a rope beaded with little diamonds cuts materials to length. Diamond-cutting ropes with circular cross-sections reduce congestion.

- Abrasive Water Jet Cutting

This cold cutting is used in fire- and blast-prone sectors. This cutting uses high-pressure water. In this cutting method, hard abrasive is forced into water. This cutting method is utilised for thick materials.

Cutting Hot Pipes

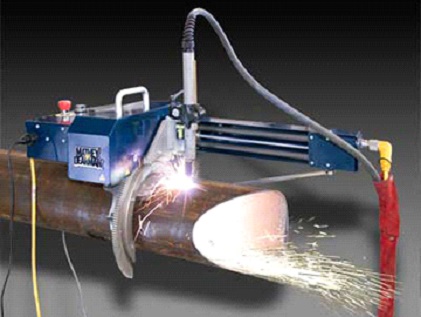

This pipe-cutting equipment uses heat to cut pipes. Hot pipe cutting has three major types.

One of the most prevalent hot pipe-cutting methods is gas or Oxy Fuel cutting. Gas type affects this process's results.

The industry loves gas cutting because it can cut 0.5mm to 250mm thick. The machine's inexpensive cost and mechanical cutting technique also make it popular.

Plasma, the fourth state of matter, sits alongside the other three. Plasma pipe cutting uses plasma torches that reach 40,000°F immediately.

Plasma flows quickly and easily through most materials. Plasma pipe cutting is speedier and can cut thick materials. This is one reason plasma cutting is used nowadays. It also saves time and money.

Laser pipe-cutting devices are utilised for fast, precise cutting thanks to technology. Laser pipe cutting accurately cuts thinner materials.

Laser cutting uses precise laser beam focus. Industries are aiming for substantial technological advances in this field as the study continues.

Different pipe cutting machines are needed for different sizes, textures, and environments. Additionally, operator and environmental safety must be considered from Pipe Cutting Machine In UAE.