Benefits of welding curtains

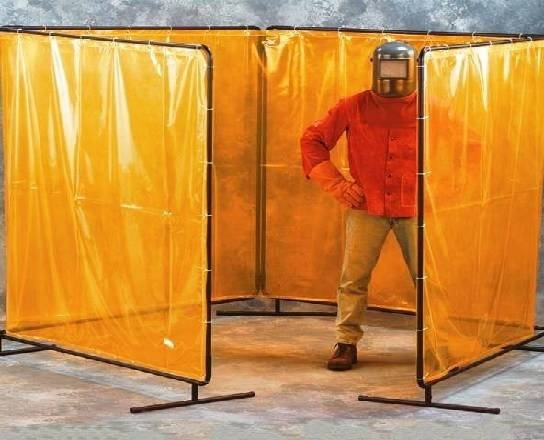

Welding curtains are essential safety equipment used to protect workers from the hazards of welding. They are made from flame-retardant materials and are designed to block harmful ultraviolet and infrared rays generated during welding. Welding curtains come in a variety of sizes, materials, and colors, and they offer several benefits that make them an essential part of any welding operation. The Cepro welding curtain is a high-quality safety equipment that effectively blocks harmful ultraviolet and infrared radiation while ensuring clear visibility for workers in the welding area. In this blog post, we will discuss the various benefits of welding curtains and how they help improve workplace safety.

Protection from Harmful Radiation

Welding produces harmful ultraviolet (UV) and infrared (IR) radiation that can cause severe damage to eyes and skin. Welding curtains are made of specialized materials that can block these harmful rays, protecting workers from exposure. The curtains act as a barrier between the welding area and the rest of the workplace, preventing radiation from reaching workers who are not wearing protective gear.

Increased Productivity

Welding curtains can increase productivity in several ways. They help to create a designated welding area, which can improve workflow and reduce interruptions. Workers can focus on their tasks without worrying about disturbing others or being interrupted by distractions. The curtains also prevent the welding light from interfering with other workers' tasks, allowing them to work safely and efficiently.

Improved Safety

Welding curtains improve safety in several ways. They help to prevent fires by blocking sparks and hot metal particles from reaching flammable materials. This reduces the risk of fire and protects workers and property from damage. Additionally, the curtains can help to contain the welding process, preventing accidents and injuries.

Customizable

Welding curtains are highly customizable and can be made to fit any workspace. They come in various sizes and colors, allowing workers to choose the best curtains for their specific needs. The curtains can also be customized with company logos or other designs, making them an excellent marketing tool for welding companies.

Cost-Effective

Welding curtains are a cost-effective solution for improving workplace safety. They are relatively inexpensive and require little maintenance. Investing in welding curtains can save money in the long run by preventing accidents and reducing the risk of property damage.

Compliance with Regulations

Welding curtains are often required by law to comply with safety regulations. The Occupational Safety and Health Administration (OSHA) has specific regulations regarding welding safety, including the use of welding curtains. Failure to comply with these regulations can result in fines, lawsuits, and other legal consequences. Using welding curtains ensures compliance with these regulations and protects businesses from legal liabilities. The durable and customizable Cepro welding curtain has become a popular choice among welding shops and industries due to its compliance with safety regulations and cost-effective benefits.

Easy to Install and Maintain

Welding curtains are easy to install and require little maintenance. They can be hung from the ceiling or mounted on a portable frame, making them highly versatile. Most curtains are made of durable materials that require minimal cleaning, and they can be easily replaced if damaged.

Improved Visibility

Welding curtains are often made of translucent materials, allowing workers to see through them while still providing protection from harmful radiation. This improves visibility and allows workers to monitor the welding process without risking exposure to harmful rays. Additionally, welding curtains can improve visibility in other ways by blocking glare and other sources of eye strain.

Environmentally Friendly

Welding curtains are environmentally friendly because they can be reused and recycled. Most curtains are made of durable materials that can withstand multiple uses, reducing waste and promoting sustainability. Additionally, some curtains are made from recycled materials, making them an even more environmentally friendly option.

Versatile

Welding curtains are highly versatile and can be used in a variety of industries and applications. They are commonly used in welding shops, but they can also be used in manufacturing, construction, and other industries that involve welding. Additionally, welding curtains can be used for other purposes beyond welding, such as partitioning work areas, creating privacy screens, or blocking out noise.

Wrapping Up:

Welding curtains offer numerous benefits to workplaces where welding is performed. They protect workers from harmful radiation, increase productivity, improve safety, and are highly customizable and cost-effective. They also comply with safety regulations, are easy to install and maintain, improve visibility, are environmentally friendly, and are highly versatile.

With its ability to block sparks and hot metal particles, the Cepro welding curtain provides an added layer of protection against fires, making it an essential safety tool in any welding operation. Overall, welding curtains are a necessary investment in workplace safety that can benefit both workers and businesses.